In the ever-evolving manufacturing industry, efficiency, precision, and cost-effectiveness are paramount. One technology that consistently excels in these areas is the cold heading machine. As a leading manufacturer in this field, our company is at the forefront of providing state-of-the-art cold forming solutions to meet various industrial needs. This article delves into the transformative impact of the cold heading machine.

The Versatility of Cold Heading Machines

Cold heading machines are a cornerstone of modern manufacturing, offering unparalleled versatility. These machines are designed to form metal at room temperature, eliminating the need for heating and thereby reducing energy consumption. This not only makes the process more environmentally friendly but also significantly lowers production costs. Our cold heading machines, including the multi station cold forging machine, are designed to handle a variety of materials, including steel, aluminum, and copper. This versatility makes them ideal for producing a wide range of components, from simple fasteners to complex automotive parts. The precision and consistency our machines provide ensure that every product meets the highest quality standards, making them indispensable in industries such as aerospace, automotive, and construction.

Cold Heading Machines: Precision and Efficiency

When it comes to manufacturing high-strength fasteners and components, cold heading machines are the preferred solution. These machines are specifically designed to form the heads of bolts, screws, and other fasteners, providing exceptional precision and strength. The cold heading process involves deforming metal under high pressure, resulting in products that are not only stronger but also more durable. Our cold heading machines are designed with cutting-edge technology to ensure maximum efficiency. They are equipped with advanced control systems that allow for precise adjustments, ensuring that each component is manufactured to exact specifications. This level of precision is crucial in industries such as aerospace and medical device manufacturing, where even the smallest deviations can lead to significant issues.

Cold Heading Machines: At the Forefront of Innovation

Innovation is at the core of our company, and our cold heading machines are a testament to this commitment. These machines are designed to push the boundaries of cold heading technology. Featuring automatic feeding systems, real-time monitoring, and adaptive control mechanisms, our cold heading machines offer unmatched performance and reliability. A standout feature is their ability to perform multiple operations within a single cycle. This not only speeds up the production process but also reduces the need for additional machinery, saving both space and costs. Additionally, the integration of advanced software allows for seamless operation and minimal downtime, ensuring that your production line runs smoothly and efficiently.

Why Choose Shengtuo?

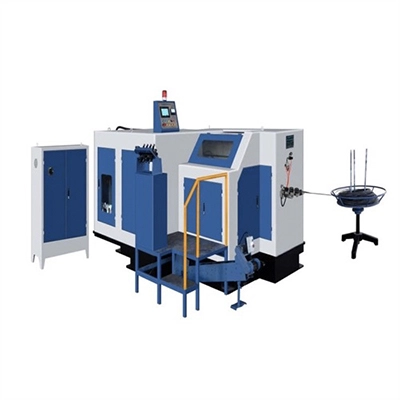

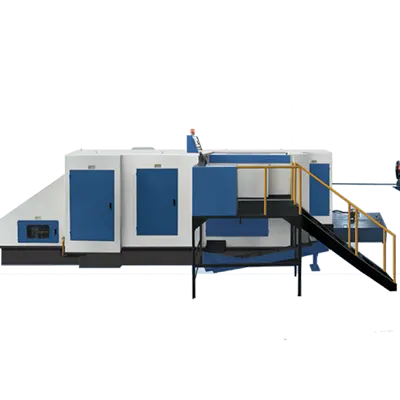

As a leading manufacturer of cold heading machines, we take pride in offering products that are not only technologically advanced but also built to last. Our machines such as high speed thread rolling machine undergo rigorous testing and quality control to ensure that they meet the highest industry standards. We also provide comprehensive after-sales support, including maintenance services and technical assistance, to ensure that your investment continues to deliver optimal performance. In summary, cold heading machines are revolutionizing the manufacturing industry. Their ability to produce high-quality components with precision and efficiency makes them invaluable in a wide range of industrial applications. As a trusted manufacturer, we are committed to delivering innovative solutions that meet the evolving needs of our customers. Invest in our cold heading machines to elevate your manufacturing capabilities to a new level.

Thread Cold Rolling Machine

ST-4R-50 High-Speed Thread Rolling Machine ST-8R-83(120) High-Speed Thread Rolling Machine ST-6R-80 High-Speed Thread Rolling Machine ST-4A-50 High-Speed Thread Rolling Machine ST-4A-25 High-Speed Thread Rolling Machine ST-10N-150 High-Speed Thread Rolling Machine ST-30N High-Speed Thread Rolling Machine ST-60N(M16-150) High-Speed Thread Rolling Machine ST-60N(M16-200) High-Speed Thread Rolling Machine ST-12N-150 High-Speed Thread Rolling Machine ST-3A-25 High-Speed Thread Rolling Machine ST-3 High-Speed Thread Rolling Machine ST-80N High-Speed Thread Rolling Machine ST-90S High-Speed Thread Rolling Machine ST-100-M40 High-Speed Thread Rolling Machine ST-70N End Milling Machine

Thread Cold Rolling Machine

ST-4R-50 High-Speed Thread Rolling Machine ST-8R-83(120) High-Speed Thread Rolling Machine ST-6R-80 High-Speed Thread Rolling Machine ST-4A-50 High-Speed Thread Rolling Machine ST-4A-25 High-Speed Thread Rolling Machine ST-10N-150 High-Speed Thread Rolling Machine ST-30N High-Speed Thread Rolling Machine ST-60N(M16-150) High-Speed Thread Rolling Machine ST-60N(M16-200) High-Speed Thread Rolling Machine ST-12N-150 High-Speed Thread Rolling Machine ST-3A-25 High-Speed Thread Rolling Machine ST-3 High-Speed Thread Rolling Machine ST-80N High-Speed Thread Rolling Machine ST-90S High-Speed Thread Rolling Machine ST-100-M40 High-Speed Thread Rolling Machine ST-70N End Milling Machine English

English 中文

中文