Thread rolling machines play a fundamental role across various industries, from metal processing to construction, ensuring precision, efficiency, and versatility. This comprehensive guide will explore different types of thread rolling machines and their applications and provide insights into choosing the best thread rolling machine manufacturers and suppliers.

Understanding Thread Rolling Machine Equipment

Thread rolling machine equipment includes a range of machines designed to shape, cut, or work raw materials into desired shapes. These machines combine heat, pressure, and mechanical force to facilitate the transformation of metals, plastics, and other materials into custom shapes and sizes. Among these, the multi station cold forging machine stands out for its ability to perform multiple operations in a single run, enhancing efficiency and precision. The type of rolling technology used often determines the quality of the final product, making the choice of the right thread rolling machine, including the advanced multi station cold forging machine, crucial for any industrial or manufacturing process.

Types of Thread Rolling Machines

Sheet Thread Rolling Machines: These machines are suitable for bending and shaping metal sheets and are commonly used in the shipbuilding, automotive, and aerospace industries. Sheet thread rolling machines can handle various thicknesses and materials, ensuring uniform bends and precise dimensions.

Rod and Bar Thread Rolling Machines: These machines are essential for producing rods and bars of different sizes and shapes, commonly found in construction, manufacturing, and engineering applications. Their versatility allows for the creation of custom profiles and improved material properties.

Ring Thread Rolling Machines: These machines are ideal for manufacturing circular or ring components, commonly used in the production of bearings, gears, and large industrial rings. They provide extremely high precision and the ability to handle high-strength materials.

Pipe and Tube Thread Rolling Machines: These machines are crucial for shaping pipes and tubes used in piping, automotive, and oil & gas industries, ensuring consistency in wall thickness and diameter. Pipe and tube thread rolling machines help streamline production while maintaining high-quality standards.

Profile Thread Rolling Machines: These machines are specifically designed for shaping long metal profiles, such as I-beams, H-beams, and angle irons. Widely used in construction and infrastructure sectors, profile thread rolling machines can create strong and structurally sound elements.

Choosing the Right Thread Rolling Machine Manufacturer and Supplier

Selecting the right thread rolling machine manufacturer and supplier can significantly impact your operations, affecting the machine's performance, durability, and overall cost-effectiveness. When looking for a high speed thread rolling machine, here are some factors to consider:

Reputation and Experience: Look for manufacturers with a good reputation and extensive experience in the industry. An established thread rolling machine manufacturer is likely to offer reliable and innovative solutions to meet your needs.

Customization and Flexibility: The ability to customize machines based on specific requirements is crucial. Leading thread rolling machine suppliers offer flexible solutions to cater to different industrial applications, ensuring optimal performance and efficiency.

After-Sales Support and Services: Comprehensive after-sales support, including maintenance, repairs, and technical assistance, is essential. Reliable suppliers will provide ongoing support to minimize downtime and extend the lifespan of thread rolling machine equipment.

Quality and Compliance: Ensure that the thread rolling machines comply with industry standards and certification requirements. High-quality machines from reputable manufacturers are more likely to deliver consistency and durability, contributing to long-term operational success.

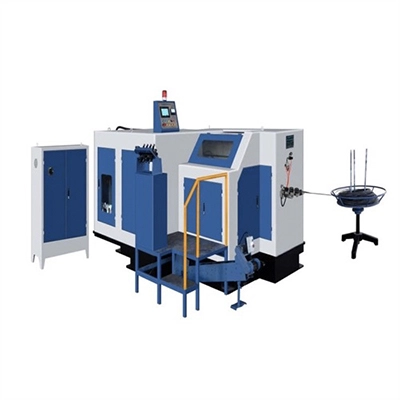

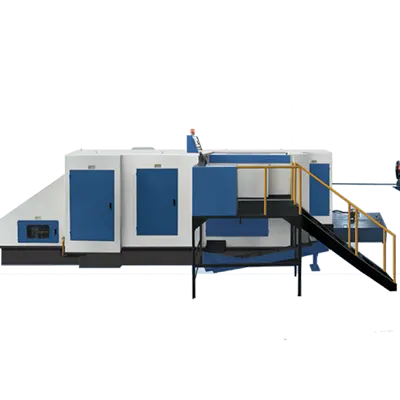

Thread Cold Rolling Machine

ST-4R-50 High-Speed Thread Rolling Machine ST-8R-83(120) High-Speed Thread Rolling Machine ST-6R-80 High-Speed Thread Rolling Machine ST-4A-50 High-Speed Thread Rolling Machine ST-4A-25 High-Speed Thread Rolling Machine ST-10N-150 High-Speed Thread Rolling Machine ST-30N High-Speed Thread Rolling Machine ST-60N(M16-150) High-Speed Thread Rolling Machine ST-60N(M16-200) High-Speed Thread Rolling Machine ST-12N-150 High-Speed Thread Rolling Machine ST-3A-25 High-Speed Thread Rolling Machine ST-3 High-Speed Thread Rolling Machine ST-80N High-Speed Thread Rolling Machine ST-90S High-Speed Thread Rolling Machine ST-100-M40 High-Speed Thread Rolling Machine ST-70N End Milling Machine

Thread Cold Rolling Machine

ST-4R-50 High-Speed Thread Rolling Machine ST-8R-83(120) High-Speed Thread Rolling Machine ST-6R-80 High-Speed Thread Rolling Machine ST-4A-50 High-Speed Thread Rolling Machine ST-4A-25 High-Speed Thread Rolling Machine ST-10N-150 High-Speed Thread Rolling Machine ST-30N High-Speed Thread Rolling Machine ST-60N(M16-150) High-Speed Thread Rolling Machine ST-60N(M16-200) High-Speed Thread Rolling Machine ST-12N-150 High-Speed Thread Rolling Machine ST-3A-25 High-Speed Thread Rolling Machine ST-3 High-Speed Thread Rolling Machine ST-80N High-Speed Thread Rolling Machine ST-90S High-Speed Thread Rolling Machine ST-100-M40 High-Speed Thread Rolling Machine ST-70N End Milling Machine English

English 中文

中文