1. Turn on the power of the riveting machine, so that we can see the power system motor and rotating gear of the machine fly.

2. We are about to place the riveted material at the center floating center of the machine mandrel, align the upper and lower holes with the floating center, and then put it again

Put the materials we need to process and let the machine begin riveting operations.

3. Step on the pedal to disengage the upper and lower clutches, and let the mold move from top to bottom to the center, so that the rivets are driven into the required position

① Do not process workpieces beyond the nominal capacity.

② Do not work under high pressure for a long time.

③ The extension length of the rivet head should not exceed the specified value.

④. Parking for maintenance immediately when encountering abnormalities, leading to troubleshooting.

4. The guide rail of the equipment should be greased once a month to make it smooth and anti-rust.

5. The assembly and disassembly of the riveting head should be gentle, especially when removing the riveting head, do not use brute force to pull it out. Rotate the riveting head and pull it out slowly. If the riveting seat of the inserted riveting head is pulled out of the normal position, there will be a significant error in the position of the riveting head after the riveting head is installed. At this time, the red safety cover should be removed and the riveting seat can be used after the riveting seat is installed in place, otherwise the machine is very simple damage.

6. In use, the riveting head will have a slight bonding phenomenon when processing certain materials. In order to ensure the quality of the riveting, the riveting head should be arranged on time to prevent the metal adhesion from thickening. Fix the rivet head on the chuck of the lathe when finishing, and then polish it with sandpaper.

7. Every two weeks, the equipment should be protected daily. The main protection items are as follows. If problems are found, they should be dealt with in time.

① Check whether the amount of smooth oil in the pneumatic triplet oil cup is sufficient, otherwise the oil cup should be filled.

② Check whether each steam pipe and joint are well connected and whether there is air leakage.

③ Check whether there is adhesion in the rivet head cavity, and arrange it if any.

④. Fill the spherical surface with smooth grease.

8. The equipment should be shut down for maintenance in batches every 6 months, and the following items should be checked. If problems are found, they should be repaired in time.

① Check whether there is air leakage in the upper and lower parts of the cylinder, otherwise the sealing ring should be replaced.

② Check whether each steam pipe and joint are well connected and whether there is air leakage.

③ Check whether the extension length of the rivet head is overrun, otherwise it should be replaced.

④ Check whether the rivet head swing is normal, otherwise stop the machine for maintenance. If it is a problem with the spherical pair, replace or repair the spherical pair in time.

⑤ Check whether the noise and riveting quality are abnormal when the spindle rotates. If so, check it. If the problem is that the bearing is worn or damaged, replace the bearing immediately.

⑥. Fill the spherical pair with smooth grease.

⑦The parts such as guide rails should be greased to make them smooth and rust-proof.

9. Special personnel should be organized to be responsible for the protection and maintenance. If you encounter problems that cannot be solved, you should contact the manufacturer in time.

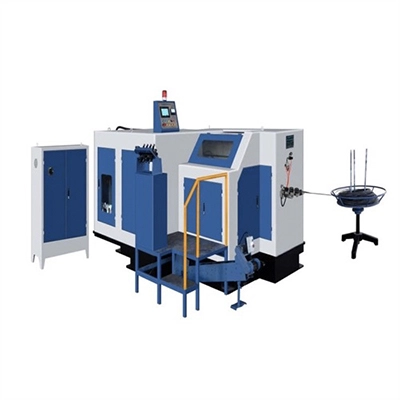

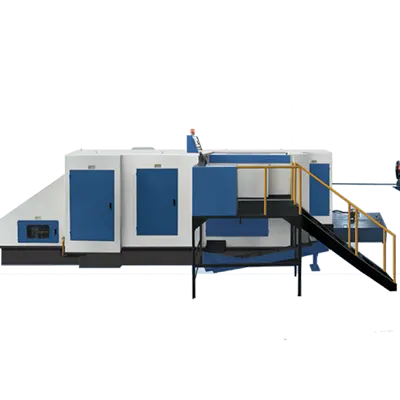

Thread Cold Rolling Machine

ST-4R-50 High-Speed Thread Rolling Machine ST-8R-83(120) High-Speed Thread Rolling Machine ST-6R-80 High-Speed Thread Rolling Machine ST-4A-50 High-Speed Thread Rolling Machine ST-4A-25 High-Speed Thread Rolling Machine ST-10N-150 High-Speed Thread Rolling Machine ST-30N High-Speed Thread Rolling Machine ST-60N(M16-150) High-Speed Thread Rolling Machine ST-60N(M16-200) High-Speed Thread Rolling Machine ST-12N-150 High-Speed Thread Rolling Machine ST-3A-25 High-Speed Thread Rolling Machine ST-3 High-Speed Thread Rolling Machine ST-80N High-Speed Thread Rolling Machine ST-90S High-Speed Thread Rolling Machine ST-100-M40 High-Speed Thread Rolling Machine ST-70N End Milling Machine

Thread Cold Rolling Machine

ST-4R-50 High-Speed Thread Rolling Machine ST-8R-83(120) High-Speed Thread Rolling Machine ST-6R-80 High-Speed Thread Rolling Machine ST-4A-50 High-Speed Thread Rolling Machine ST-4A-25 High-Speed Thread Rolling Machine ST-10N-150 High-Speed Thread Rolling Machine ST-30N High-Speed Thread Rolling Machine ST-60N(M16-150) High-Speed Thread Rolling Machine ST-60N(M16-200) High-Speed Thread Rolling Machine ST-12N-150 High-Speed Thread Rolling Machine ST-3A-25 High-Speed Thread Rolling Machine ST-3 High-Speed Thread Rolling Machine ST-80N High-Speed Thread Rolling Machine ST-90S High-Speed Thread Rolling Machine ST-100-M40 High-Speed Thread Rolling Machine ST-70N End Milling Machine English

English 中文

中文