The riveting machine can be divided into many types according to the structure type. There are sliding rail type and turntable type, but the principle is completely different. They are all set to move the workpiece to the riveting area, and then the active riveting machine ends the riveting skills. Maintenance method of riveting machine:

1. Do not process workpieces beyond the nominal talent.

2. Do not work under high pressure for a long time.

3. The extension length of the rivet head should not exceed the specified value.

4. If there is an abnormality, the car will be repaired immediately, and the fault will be cleaned.

5. The guide rail of the equipment should be greased once a month to make it smooth and anti-rust.

6. The assembly and disassembly of the riveting head should be slow, especially when the riveting head is disassembled, do not use brute force to pull it out. Rotate the riveting head and pull it out slowly. Assuming that the riveting seat of the plug-in riveting head is pulled out of the normal orientation, the orientation of the riveting head after the equipment riveting head will show an obvious fault. At this moment, the red safety cover should be removed and the riveting seat equipment can be used after it is in place, otherwise the machine will be simply damaged. .

7. In use, the riveting head will show a slender bonding appearance when processing certain materials. In order to ensure the quality of the riveting, the riveting head should be cleaned up on time to prevent the metal adhesion from thickening. When cleaning, fix the rivet head on the chuck of the lathe, and then polish it with sandpaper.

8. The equipment should be maintained normally every two weeks. The main maintenance items are as follows. If problems are found, they should be dealt with in time.

① Check whether the smooth oil in the pneumatic triplet oil cup is sufficient, otherwise the oil cup should be filled.

②. Check whether each steam pipe and joint are connected to Jianwang, and whether there is a sign of air leakage.

③. Check whether there is any adhesive appearance in the rivet head cavity, and clean up if there is any.

④. Fill the spherical surface with smooth grease.

9. The equipment should be stopped and repaired in batches every 6 months, and the following items should be checked first. If problems are found, they should be repaired in time.

① Check whether there are signs of air leakage on the upper and lower cylinders, otherwise the sealing ring should be replaced.

②. Check whether each steam pipe and joint are connected to Jianwang, and whether there is a sign of air leakage.

③ Check whether the extension length of the rivet head exceeds the standard, otherwise it should be replaced.

④. Check whether the shaking of the riveting head is normal, otherwise stop the machine for repair, if it is a problem with the spherical surface, replace or modify the spherical surface in time.

⑤ Check whether the noise and riveting quality of the main shaft are abnormal. If so, check it. If the problem is that the bearing is worn or damaged, replace the bearing immediately.

⑥. Fill the spherical pair with smooth grease.

⑦The parts such as guide rails should be greased to make them smooth and rust-proof.

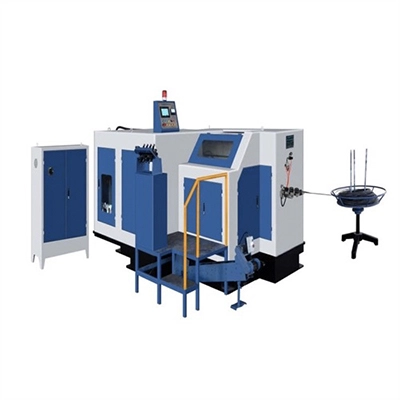

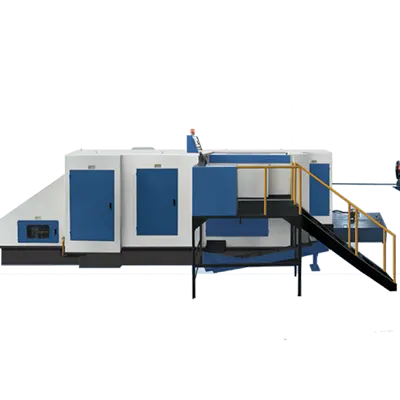

Thread Cold Rolling Machine

ST-4R-50 High-Speed Thread Rolling Machine ST-8R-83(120) High-Speed Thread Rolling Machine ST-6R-80 High-Speed Thread Rolling Machine ST-4A-50 High-Speed Thread Rolling Machine ST-4A-25 High-Speed Thread Rolling Machine ST-10N-150 High-Speed Thread Rolling Machine ST-30N High-Speed Thread Rolling Machine ST-60N(M16-150) High-Speed Thread Rolling Machine ST-60N(M16-200) High-Speed Thread Rolling Machine ST-12N-150 High-Speed Thread Rolling Machine ST-3A-25 High-Speed Thread Rolling Machine ST-3 High-Speed Thread Rolling Machine ST-80N High-Speed Thread Rolling Machine ST-90S High-Speed Thread Rolling Machine ST-100-M40 High-Speed Thread Rolling Machine ST-70N End Milling Machine

Thread Cold Rolling Machine

ST-4R-50 High-Speed Thread Rolling Machine ST-8R-83(120) High-Speed Thread Rolling Machine ST-6R-80 High-Speed Thread Rolling Machine ST-4A-50 High-Speed Thread Rolling Machine ST-4A-25 High-Speed Thread Rolling Machine ST-10N-150 High-Speed Thread Rolling Machine ST-30N High-Speed Thread Rolling Machine ST-60N(M16-150) High-Speed Thread Rolling Machine ST-60N(M16-200) High-Speed Thread Rolling Machine ST-12N-150 High-Speed Thread Rolling Machine ST-3A-25 High-Speed Thread Rolling Machine ST-3 High-Speed Thread Rolling Machine ST-80N High-Speed Thread Rolling Machine ST-90S High-Speed Thread Rolling Machine ST-100-M40 High-Speed Thread Rolling Machine ST-70N End Milling Machine English

English 中文

中文