The transport bridge is selected to send to the nailing, so that the production of the operating table is connected with each other, which is a key component to maintain the continuous and intelligent process flow. Especially in textile machinery, the use of the work efficiency of the transport bridge can improve the employment standards, reduce the auxiliary labor, and increase the labor productivity.

How much is the price range of the boltless riveting machine? Usually the cabinet-type boltless riveting machine costs 30,000 to 50,000; the infrared sensor marking anti-pressure hand boltless riveting machine is usually 20,000 to 30,000; the boltless riveting of cable bridges is basically 20,000 to 30,000. ; Gas-liquid booster boltless riveting machine is usually 10,000 to 20,000; wind pressure boltless riveting machine is also in the range of 10,000 to 20,000.

Riveting and extrusion processing has all kinds of shapes. The most widely used are ring shapes, trilateral shapes, four nautical miles, or arc shapes. This kind of important is limited by the common problems of riveting parts, such as riveting square steel grooves on rigid plates. Assuming that other extrusion processing methods are used for this kind of milling machine processing is very complicated, and the quality is not comfortable and suitable for the guarantor, at this moment, you require the use of riveting machines. In many night pressure parts and hydraulic parts, the process flow hole or the oil feed inlet is therefore tightly opened by steel balls. Some requirements of this kind of strict open type are movable, such as the fuel inlet, the oil cup, etc., the steel ball can be pressed in and restored; some, like the process hole, the steel ball is required to be clear and tight open closed fuel pipe And no oil leakage, no dislocation. The extrusion processing of this kind of spare parts is the area where the riveting machine is very popular. If the CNC milling machine is adjusted, the pre-stressed tensioning, pressing and riveting of the steel ball can be carried out several times, with high production efficiency and high cost performance.

The work of the self-piercing spin riveting machine is that the blank holder first moves downwards to pre-tension the riveted material to prevent the material from swimming into the die under the inertial force of the bolt. The core punching needle Work downwards to encourage the bolts to pierce through the top material. Under the mutual effect of the die and the punching needle, the end of the bolt is stretched out in the next layer of alloy to produce a bell mouth that is convenient for locking, which exceeds the purpose of connection.

Willing to immediately press the riveting method to improve work efficiency. After the axial spin riveting machine is connected to the power source, only the oil pump motor button (do not move the spindle motor button) is turned on, and the foot switch is immediately pressed. The effect of riveting is very good.

The automatic riveting machine is the whole process of drilling holes in harmony with each other from five positions. Initially move the material to the area where the camera head of the automatic riveting machine scans the surface. After the camera scans the image, the camera will process it and send it to the control position signal. After the control position receives the signal, it will advance the processing and control the position and attitude of the gearbox. , Make the punching needle move on the X-axis and V-axis on the spherical surface, and start the work after starting the moving posture, and the solenoid valve controls the cylinder to perform the punching posture. All the postures of the automatic riveting machine can be achieved with one wave, fast, accurate and efficient.

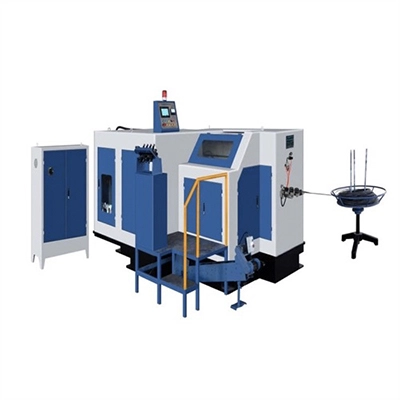

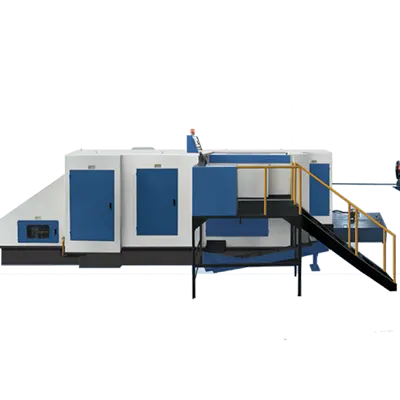

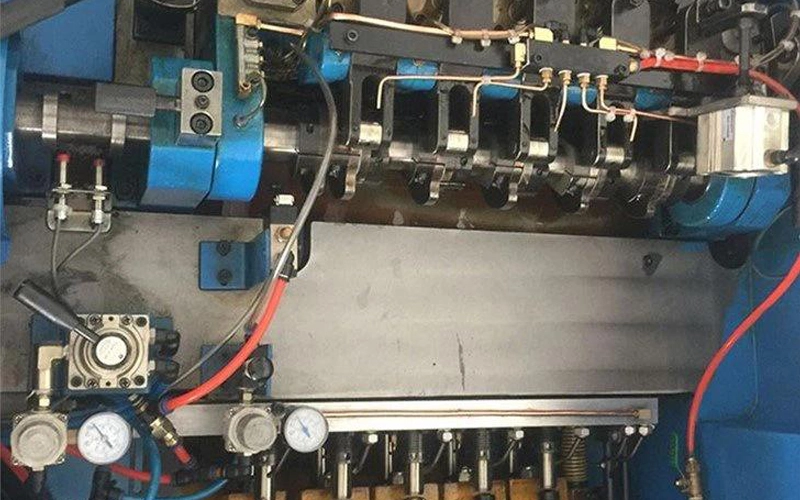

Thread Cold Rolling Machine

ST-4R-50 High-Speed Thread Rolling Machine ST-8R-83(120) High-Speed Thread Rolling Machine ST-6R-80 High-Speed Thread Rolling Machine ST-4A-50 High-Speed Thread Rolling Machine ST-4A-25 High-Speed Thread Rolling Machine ST-10N-150 High-Speed Thread Rolling Machine ST-30N High-Speed Thread Rolling Machine ST-60N(M16-150) High-Speed Thread Rolling Machine ST-60N(M16-200) High-Speed Thread Rolling Machine ST-12N-150 High-Speed Thread Rolling Machine ST-3A-25 High-Speed Thread Rolling Machine ST-3 High-Speed Thread Rolling Machine ST-80N High-Speed Thread Rolling Machine ST-90S High-Speed Thread Rolling Machine ST-100-M40 High-Speed Thread Rolling Machine ST-70N End Milling Machine

Thread Cold Rolling Machine

ST-4R-50 High-Speed Thread Rolling Machine ST-8R-83(120) High-Speed Thread Rolling Machine ST-6R-80 High-Speed Thread Rolling Machine ST-4A-50 High-Speed Thread Rolling Machine ST-4A-25 High-Speed Thread Rolling Machine ST-10N-150 High-Speed Thread Rolling Machine ST-30N High-Speed Thread Rolling Machine ST-60N(M16-150) High-Speed Thread Rolling Machine ST-60N(M16-200) High-Speed Thread Rolling Machine ST-12N-150 High-Speed Thread Rolling Machine ST-3A-25 High-Speed Thread Rolling Machine ST-3 High-Speed Thread Rolling Machine ST-80N High-Speed Thread Rolling Machine ST-90S High-Speed Thread Rolling Machine ST-100-M40 High-Speed Thread Rolling Machine ST-70N End Milling Machine English

English 中文

中文