The purchase of materials is only the most basic step in assembling equipment, and the next equipment assembly is the most important. Because there will be some errors between the drawings and the actual items during the production process. Sometimes it is precisely because of these small differences that various problems appear in the finished product. Therefore, it is necessary for the assembler to find and solve these problems carefully, so as to reduce unnecessary problems in the subsequent debugging. In addition, there is a problem of strength in the assembly process, that is, cleverness. Because some parts do not need to be screwed to death, they can meet the requirements of use, and it is not good to screw them too tightly. However, some places need to be tightened, and problems may occur if they are loose. In fact, this depends on the actual assembly situation. In a word, it is two words: flexible. For skilled masters, these problems are as simple as drinking water and eating, but novices need to accumulate more experience.

The manufacturing industry reflects the productivity level of a country and occupies a very important share in the national economy of developed countries in the world. my country's manufacturing industry is also a pillar industry of the country. With the increase of labor costs in our country, more and more domestic labor-intensive industries have been transferred to Southeast Asia, but after arriving in Southeast Asia, many enterprises are not acclimatized. Because although the local labor cost has been reduced, many industrial chains are not perfect, and the quality of many workers cannot keep up. At this time, the production efficiency will be greatly reduced. So how did the domestic manufacturers develop?

This requires manufacturers to improve the level of automation and purchase corresponding automation equipment. For example, the process of locking screws is also a headache for many companies. In order to meet the market demand, in recent years, there have been many automatic locking screw machine manufacturers in China, and they have indeed helped many companies solve this problem. However, after many manufacturers introduce equipment, the subsequent equipment maintenance is a headache. Because there are many non-standard customizations of this type of equipment, many companies that use the equipment do not have professional technical personnel and can only rely on equipment manufacturers. Subsequent product line changes, equipment aging, and parts replacement will be very passive. Therefore, before purchasing an equipment manufacturer, it is necessary to conduct an in-depth investigation of the equipment manufacturer. Not only the production scale must be inspected, but more importantly, the production process, material selection, and logistics support must be considered. The logistics support depends on the staffing of after-sales engineers, the layout of the site, the safety stock of spare parts in the warehouse, and so on.

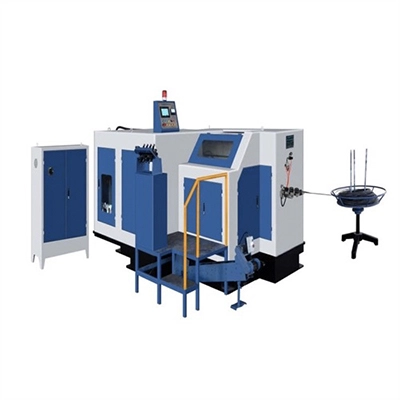

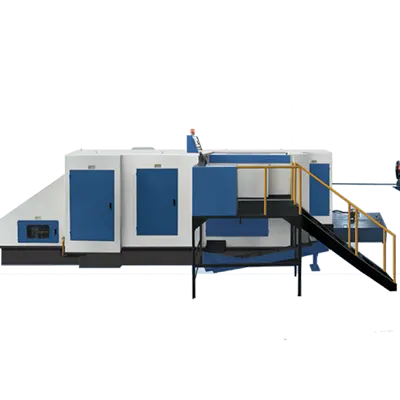

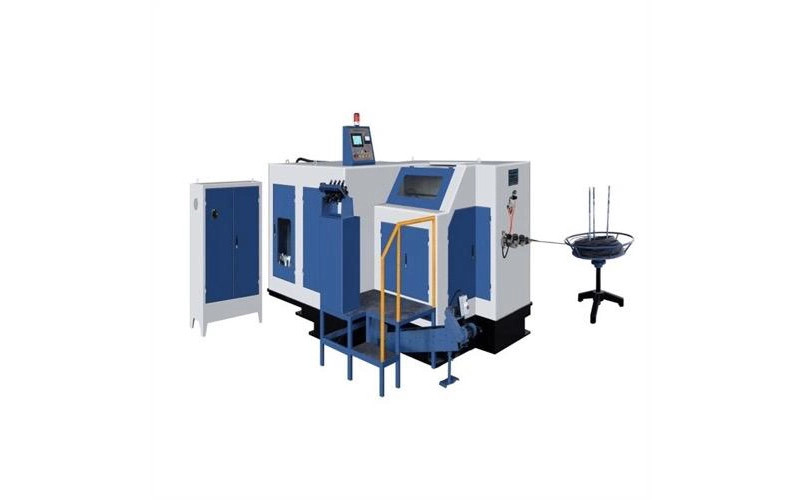

Thread Cold Rolling Machine

ST-4R-50 High-Speed Thread Rolling Machine ST-8R-83(120) High-Speed Thread Rolling Machine ST-6R-80 High-Speed Thread Rolling Machine ST-4A-50 High-Speed Thread Rolling Machine ST-4A-25 High-Speed Thread Rolling Machine ST-10N-150 High-Speed Thread Rolling Machine ST-30N High-Speed Thread Rolling Machine ST-60N(M16-150) High-Speed Thread Rolling Machine ST-60N(M16-200) High-Speed Thread Rolling Machine ST-12N-150 High-Speed Thread Rolling Machine ST-3A-25 High-Speed Thread Rolling Machine ST-3 High-Speed Thread Rolling Machine ST-80N High-Speed Thread Rolling Machine ST-90S High-Speed Thread Rolling Machine ST-100-M40 High-Speed Thread Rolling Machine ST-70N End Milling Machine

Thread Cold Rolling Machine

ST-4R-50 High-Speed Thread Rolling Machine ST-8R-83(120) High-Speed Thread Rolling Machine ST-6R-80 High-Speed Thread Rolling Machine ST-4A-50 High-Speed Thread Rolling Machine ST-4A-25 High-Speed Thread Rolling Machine ST-10N-150 High-Speed Thread Rolling Machine ST-30N High-Speed Thread Rolling Machine ST-60N(M16-150) High-Speed Thread Rolling Machine ST-60N(M16-200) High-Speed Thread Rolling Machine ST-12N-150 High-Speed Thread Rolling Machine ST-3A-25 High-Speed Thread Rolling Machine ST-3 High-Speed Thread Rolling Machine ST-80N High-Speed Thread Rolling Machine ST-90S High-Speed Thread Rolling Machine ST-100-M40 High-Speed Thread Rolling Machine ST-70N End Milling Machine English

English 中文

中文