The coordinate type automatic locking screw machine has strong self-reliance. Equipment maintenance and maintenance are mainly operated through the man-machine interface. Equipment failures will be displayed on the touch screen. If the equipment is abnormal, the operation interface will have relevant prompts. The automatic locking screw machine is a non-standard equipment. Each model has its own operating system. The operating system is usually programmed by the screw machine manufacturer independently. The products and procedures of each industry are different. The technology introduced here is only applicable to the coordinate automatic locking screw. machine.

Common problems of coordinate automatic locking screw machine

1. Coordinate type automatic locking screw machine with mechanical hand locking screw machine is mainly composed of screw feeding system, multi-axis locking system, automatic grasping system, and multi-station workbench. Multi-system cooperation and synchronous operation, common problems are mainly introduced Problems and solutions in the application of locking system and grasping system of automatic screw machine.

2. The system cannot be started: check whether the start light is normal, if not, check the start button and clear; whether the magnetic ring on the lifting cylinder is normal, if not normal, check whether the magnetic ring is good or not and check clearly; whether it is in automatic mode ; Whether the emergency stop signal is normal, if not normal, check the emergency stop button and clear; whether the magnetic ring on the robot hand or the magnetic ring is normal, if not normal, check whether the magnetic ring is good or not and check it clearly.

3. The turntable does not rotate after the system is started: check whether the drive motor of the turntable is rotating. If not, use a multimeter AC750 to measure the drive motor of the turntable and control the power supply to see whether there is AC220V. If there is voltage, the motor is damaged; check the brake and clutch Whether to start.

4. The electric batch or air batch does not turn during the lowering process after the system is started: check whether the magnetic ring in the lifting cylinder is normal.

5. The coordinate type automatic locking screw machine does not rise when the screw is turned: check whether the magnetic ring under the lifting cylinder is normal.

6. The coordinate type automatic locking screw machine does not feed the screw after the screw is turned up to the position: check whether the screw is stuck in the nail feeding machine, whether the power source of the nail feeding machine is normal; check whether the magnetic ring on the lifting cylinder is normal.

7. The manipulator of the coordinate type automatic locking screw machine does not work: check whether the function of the manipulator is enabled; check whether the magnetic ring on the manipulator, the magnetic ring of the grasping position, and the magnetic ring opened by fingers are normal.

8. The robot arm cannot catch the product: check whether the product is stuck; check whether the magnetic ring of the fingers is normal.

9. When the manipulator reaches the position and does not put the product: check whether the magnetic ring of the manipulator is normal; check whether the movement of the finger cylinder is normal.

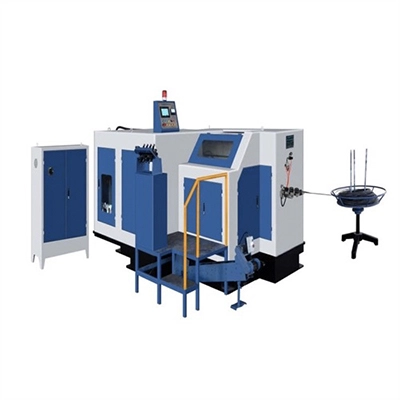

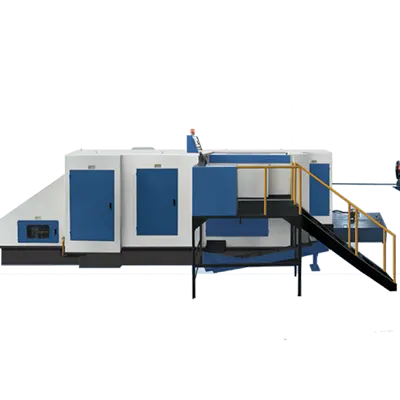

Thread Cold Rolling Machine

ST-4R-50 High-Speed Thread Rolling Machine ST-8R-83(120) High-Speed Thread Rolling Machine ST-6R-80 High-Speed Thread Rolling Machine ST-4A-50 High-Speed Thread Rolling Machine ST-4A-25 High-Speed Thread Rolling Machine ST-10N-150 High-Speed Thread Rolling Machine ST-30N High-Speed Thread Rolling Machine ST-60N(M16-150) High-Speed Thread Rolling Machine ST-60N(M16-200) High-Speed Thread Rolling Machine ST-12N-150 High-Speed Thread Rolling Machine ST-3A-25 High-Speed Thread Rolling Machine ST-3 High-Speed Thread Rolling Machine ST-80N High-Speed Thread Rolling Machine ST-90S High-Speed Thread Rolling Machine ST-100-M40 High-Speed Thread Rolling Machine ST-70N End Milling Machine

Thread Cold Rolling Machine

ST-4R-50 High-Speed Thread Rolling Machine ST-8R-83(120) High-Speed Thread Rolling Machine ST-6R-80 High-Speed Thread Rolling Machine ST-4A-50 High-Speed Thread Rolling Machine ST-4A-25 High-Speed Thread Rolling Machine ST-10N-150 High-Speed Thread Rolling Machine ST-30N High-Speed Thread Rolling Machine ST-60N(M16-150) High-Speed Thread Rolling Machine ST-60N(M16-200) High-Speed Thread Rolling Machine ST-12N-150 High-Speed Thread Rolling Machine ST-3A-25 High-Speed Thread Rolling Machine ST-3 High-Speed Thread Rolling Machine ST-80N High-Speed Thread Rolling Machine ST-90S High-Speed Thread Rolling Machine ST-100-M40 High-Speed Thread Rolling Machine ST-70N End Milling Machine English

English 中文

中文