If the air is too humid, some metal components in the automatic screw machine will rust. Therefore, it should be ensured that the screw machine is used in a workshop with excellent ventilation and relatively dry (lack of moisture). In addition, there should be a lot of avoidance in the workshop. Dust is flying, especially metal dust is not allowed to avoid dust entering the screw machine and causing damage to important components.

In order to maintain the outstanding function of the automatic screw machine and avoid problems caused by external factors, the residue in the screw vibration plate should be regularly sorted and the plate should be kept clean, and the special-shaped screws should be taken out in time to prevent the photoelectric switch of the vibration plate from being affected. disturb. The screw machine manufacturer is composed of a feeding system and a pay lock system. The feeding part, also known as the screw placement machine and the screw supply machine, is a relatively simple way of arranging the screws in a row for the purpose of improving work efficiency. This kind of small automation equipment is widely used in the electronics industry.

The screw machine manufacturer is a small machine that automatically locks screws, and quality and functional stability are the most critical. At the same time, do not put some tools and irrelevant products on the surface of the machine to prevent the moving parts of the screw machine from being stuck and damaged. 3. When the equipment is not in use, the power and air source of the automatic screw machine should be closed to avoid letting the screw machine. Always adhere to the charged state, because even if it does not start running, there will be a weak current in the circuit as long as the power is turned on. If this happens, it will cause damage to the circuit and accelerate the aging of the circuit wires.

During the use of the automatic screw machine, the plug-in and ventilation of the screw machine should be checked regularly (check and test) to ensure that the air pressure is stable within the specified pressure range, and the function of the screw machine should also be checked in order to persist during use Best state.

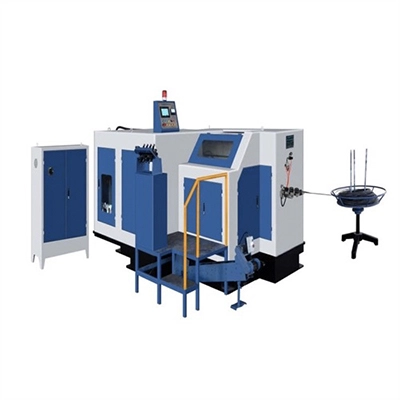

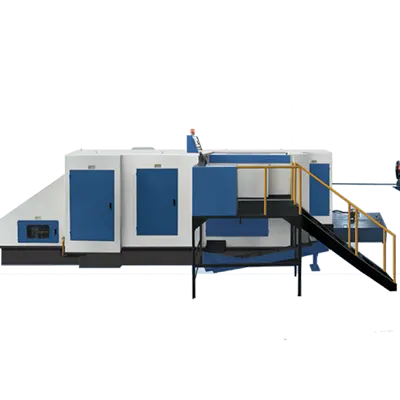

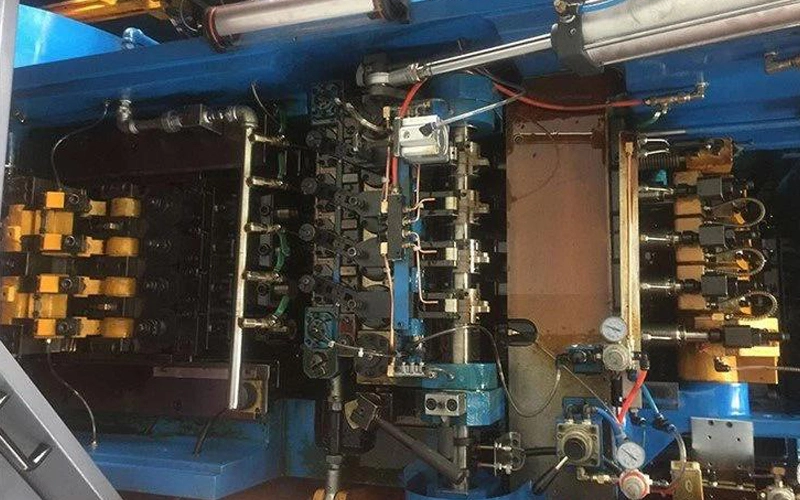

Thread Cold Rolling Machine

ST-4R-50 High-Speed Thread Rolling Machine ST-8R-83(120) High-Speed Thread Rolling Machine ST-6R-80 High-Speed Thread Rolling Machine ST-4A-50 High-Speed Thread Rolling Machine ST-4A-25 High-Speed Thread Rolling Machine ST-10N-150 High-Speed Thread Rolling Machine ST-30N High-Speed Thread Rolling Machine ST-60N(M16-150) High-Speed Thread Rolling Machine ST-60N(M16-200) High-Speed Thread Rolling Machine ST-12N-150 High-Speed Thread Rolling Machine ST-3A-25 High-Speed Thread Rolling Machine ST-3 High-Speed Thread Rolling Machine ST-80N High-Speed Thread Rolling Machine ST-90S High-Speed Thread Rolling Machine ST-100-M40 High-Speed Thread Rolling Machine ST-70N End Milling Machine

Thread Cold Rolling Machine

ST-4R-50 High-Speed Thread Rolling Machine ST-8R-83(120) High-Speed Thread Rolling Machine ST-6R-80 High-Speed Thread Rolling Machine ST-4A-50 High-Speed Thread Rolling Machine ST-4A-25 High-Speed Thread Rolling Machine ST-10N-150 High-Speed Thread Rolling Machine ST-30N High-Speed Thread Rolling Machine ST-60N(M16-150) High-Speed Thread Rolling Machine ST-60N(M16-200) High-Speed Thread Rolling Machine ST-12N-150 High-Speed Thread Rolling Machine ST-3A-25 High-Speed Thread Rolling Machine ST-3 High-Speed Thread Rolling Machine ST-80N High-Speed Thread Rolling Machine ST-90S High-Speed Thread Rolling Machine ST-100-M40 High-Speed Thread Rolling Machine ST-70N End Milling Machine English

English 中文

中文