Screws are small parts that are often seen in daily life. Screws not only provide a lot of convenience in life, but also act as a very important component in industry. In the past, manual manufacturing and production of screws was relatively laborious, and consumed a lot of labor and material resources. In order to reduce expensive labor costs and increase production capacity, relevant staff have planned active screw-locking equipment. With the emergence of active screw-locking machines, the progress of some occupations has become more and more rapid.

The active locking screw machine has become an indispensable part of industrial production. The use of the active locking screw machine not only greatly improves the industrial production power, but also saves costs. At the same time, the quality of the products has been improved, which has a great effect on the development of occupations and the process of industrial automation.

The occupations involved in the active screw machine have these aspects. Communication occupations: such as mobile phone active screwing machine, camera, hard disk, keyboard automatic screwing machine, printer, computer, DVD, home appliance automatic screwing machine, plastic, toy automatic screwing machine, electrical appliances, communication equipment, toys, electronic processing assembly And other categories. Screws are indispensable parts for these products. By using an active screw-locking machine, higher power can be achieved in the assembly and production process.

Auto career. The production and assembly of automobiles are completed by many processes. In many processes, only the screwing process requires a lot of labor, and it also seriously affects the progress of production power, cost and production standards. Therefore, in order to seek automation, many auto parts, or most parts of the entire vehicle manufacturer, use an active screw machine to complete the screw fastening process.

The toy takes the initiative to drive the screw machine. The occupational employment of toys is densely populated, which is characterized by large output and short product life cycle. Due to the continuous innovation of products and a wide variety of products, many toy screw locks still use more traditional methods (screw trays, placement machines, etc.). ), this part of the process has a significant impact on toy costs. And it is undoubtedly a good choice to choose an active screw machine.

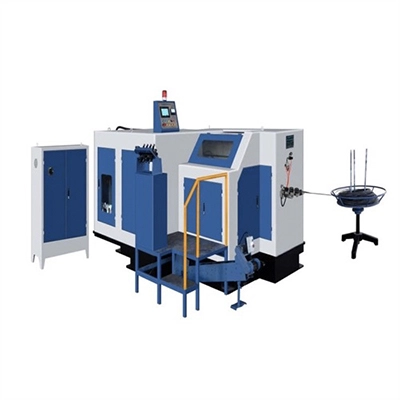

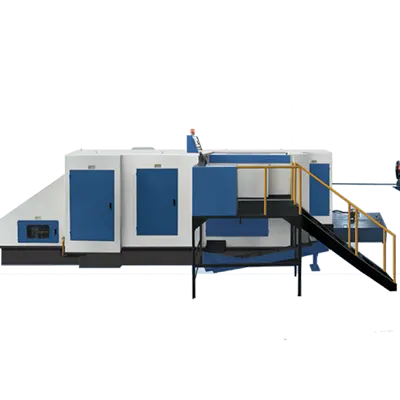

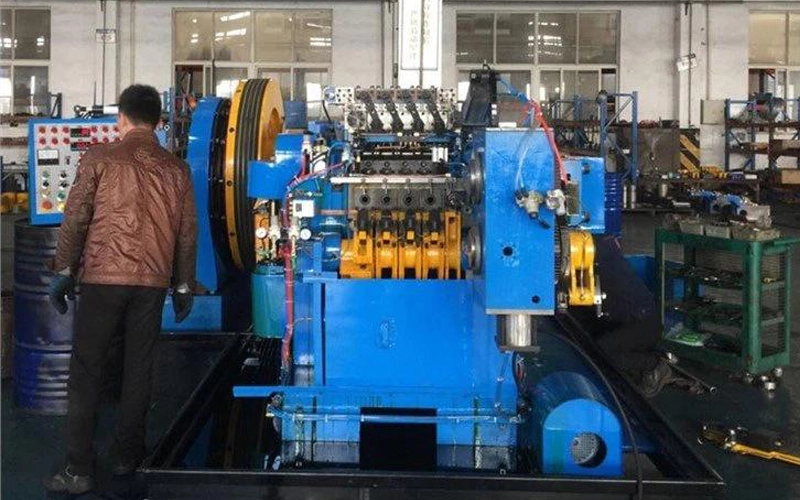

Thread Cold Rolling Machine

ST-4R-50 High-Speed Thread Rolling Machine ST-8R-83(120) High-Speed Thread Rolling Machine ST-6R-80 High-Speed Thread Rolling Machine ST-4A-50 High-Speed Thread Rolling Machine ST-4A-25 High-Speed Thread Rolling Machine ST-10N-150 High-Speed Thread Rolling Machine ST-30N High-Speed Thread Rolling Machine ST-60N(M16-150) High-Speed Thread Rolling Machine ST-60N(M16-200) High-Speed Thread Rolling Machine ST-12N-150 High-Speed Thread Rolling Machine ST-3A-25 High-Speed Thread Rolling Machine ST-3 High-Speed Thread Rolling Machine ST-80N High-Speed Thread Rolling Machine ST-90S High-Speed Thread Rolling Machine ST-100-M40 High-Speed Thread Rolling Machine ST-70N End Milling Machine

Thread Cold Rolling Machine

ST-4R-50 High-Speed Thread Rolling Machine ST-8R-83(120) High-Speed Thread Rolling Machine ST-6R-80 High-Speed Thread Rolling Machine ST-4A-50 High-Speed Thread Rolling Machine ST-4A-25 High-Speed Thread Rolling Machine ST-10N-150 High-Speed Thread Rolling Machine ST-30N High-Speed Thread Rolling Machine ST-60N(M16-150) High-Speed Thread Rolling Machine ST-60N(M16-200) High-Speed Thread Rolling Machine ST-12N-150 High-Speed Thread Rolling Machine ST-3A-25 High-Speed Thread Rolling Machine ST-3 High-Speed Thread Rolling Machine ST-80N High-Speed Thread Rolling Machine ST-90S High-Speed Thread Rolling Machine ST-100-M40 High-Speed Thread Rolling Machine ST-70N End Milling Machine English

English 中文

中文