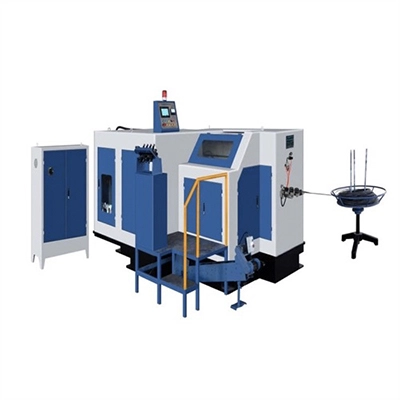

The automatic screwing machine is to complete the automatic conveying, tightening, testing and other processes of screws through various electric and pneumatic components, and simplify the screw tightening process through equipment, so as to reduce the number of labor and reduce the bad elements caused by manual misoperation. It is a typical non-standard automation equipment. Automatic locking screw machine is mainly divided into: hand-held screw locking machine, multi-axis automatic locking screw machine, coordinate automatic locking screw machine.

Automatic screwing machine The automatic locking screw machine is mainly used for the locking of M1-M8 screws. Because it belongs to non-standard automation equipment, it has customizable characteristics, and products involving screw fastening can obtain corresponding treatment plans, and the application range is relatively common. The automatic locking screw machine is to complete the automatic conveying, tightening, testing and other processes of screws through various types of electro-pneumatic components, and to simplify the screw tightening process through equipment, so as to reduce the number of labor and reduce the bad elements caused by manual misoperation. It is a typical non-standard automation equipment.

Versatility is strong. Small in size, it can be used with production line operations, and it is convenient to change products. The number of Z-axis electric batches can be customized according to customer requirements, and 2 electric batches can work at the same time to replace multiple workers; Reduce the labor intensity of workers. The traditional requirement of manually placing screws and aligning the screw heads takes up a lot of work time and effort. High level of automation. The operation is simple, and the staff quickly controls the operation and debugging. One worker can manage several machines at the same time. Save labor. Torque is accurate. Conditioning convenience, to ensure the quality of locking. The applicable screw range is more general.

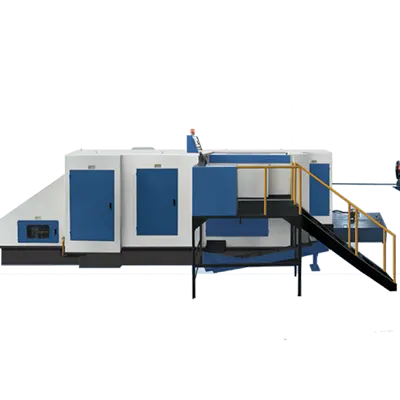

Thread Cold Rolling Machine

ST-4R-50 High-Speed Thread Rolling Machine ST-8R-83(120) High-Speed Thread Rolling Machine ST-6R-80 High-Speed Thread Rolling Machine ST-4A-50 High-Speed Thread Rolling Machine ST-4A-25 High-Speed Thread Rolling Machine ST-10N-150 High-Speed Thread Rolling Machine ST-30N High-Speed Thread Rolling Machine ST-60N(M16-150) High-Speed Thread Rolling Machine ST-60N(M16-200) High-Speed Thread Rolling Machine ST-12N-150 High-Speed Thread Rolling Machine ST-3A-25 High-Speed Thread Rolling Machine ST-3 High-Speed Thread Rolling Machine ST-80N High-Speed Thread Rolling Machine ST-90S High-Speed Thread Rolling Machine ST-100-M40 High-Speed Thread Rolling Machine ST-70N End Milling Machine

Thread Cold Rolling Machine

ST-4R-50 High-Speed Thread Rolling Machine ST-8R-83(120) High-Speed Thread Rolling Machine ST-6R-80 High-Speed Thread Rolling Machine ST-4A-50 High-Speed Thread Rolling Machine ST-4A-25 High-Speed Thread Rolling Machine ST-10N-150 High-Speed Thread Rolling Machine ST-30N High-Speed Thread Rolling Machine ST-60N(M16-150) High-Speed Thread Rolling Machine ST-60N(M16-200) High-Speed Thread Rolling Machine ST-12N-150 High-Speed Thread Rolling Machine ST-3A-25 High-Speed Thread Rolling Machine ST-3 High-Speed Thread Rolling Machine ST-80N High-Speed Thread Rolling Machine ST-90S High-Speed Thread Rolling Machine ST-100-M40 High-Speed Thread Rolling Machine ST-70N End Milling Machine English

English 中文

中文