Cold forging is a precision manufacturing process that shapes metal at room temperature or slightly below its recrystallization point. Unlike traditional hot forging, which involves heating the metal, cold forging relies on high pressure to deform the material into the desired shape. This method is widely used in industries such as automotive, aerospace, electronics, and more due to its efficiency, precision, and cost-effectiveness.

In this article, we’ll explore the cold forging process, its advantages, and why Shengtuo Machine is your go-to expert for cold forging solutions.

How Does Cold Forging Work?

Cold forging involves several key steps:

Material Selection: High-quality metals like aluminum, steel, or copper are chosen for their ductility and strength.

Lubrication: The metal is lubricated to reduce friction and prevent damage during the forging process.

Forming: The metal is placed in a die and subjected to high pressure using a punch or hammer, shaping it into the desired form.

Finishing: The forged part may undergo additional processes like trimming, heat treatment, or surface finishing for enhanced durability and appearance.

Advantages of Cold Forging

Higher Strength: Cold forging increases the metal’s density, resulting in stronger and more durable components.

Cost Efficiency: The process minimizes material waste and reduces the need for secondary machining.

Improved Precision: Cold forging produces parts with tight tolerances and excellent surface finishes.

Environmentally Friendly: No heating means lower energy consumption and reduced carbon emissions.

Mass Production: Ideal for high-volume manufacturing due to its speed and consistency.

Applications of Cold Forging

Cold forging is used to produce a wide range of components, including:

Automotive parts (e.g., gears, shafts, and bolts)

Aerospace components (e.g., fasteners and structural parts)

Electronics (e.g., connectors and housings)

Industrial machinery (e.g., tools and fittings)

Why Choose Shengtuo Machine for Cold Forging?

At Shengtuo Machine, we specialize in providing cutting-edge cold forging solutions tailored to your needs. Here’s why we stand out:

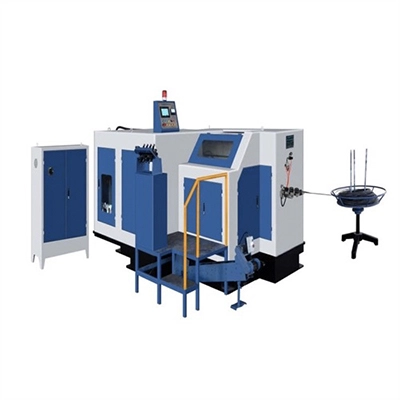

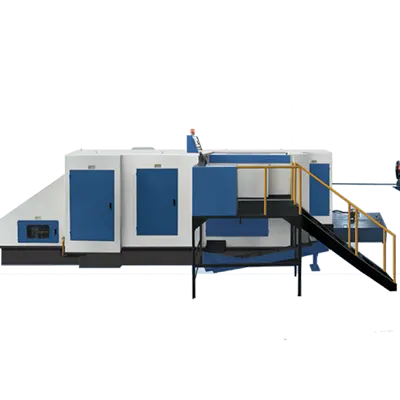

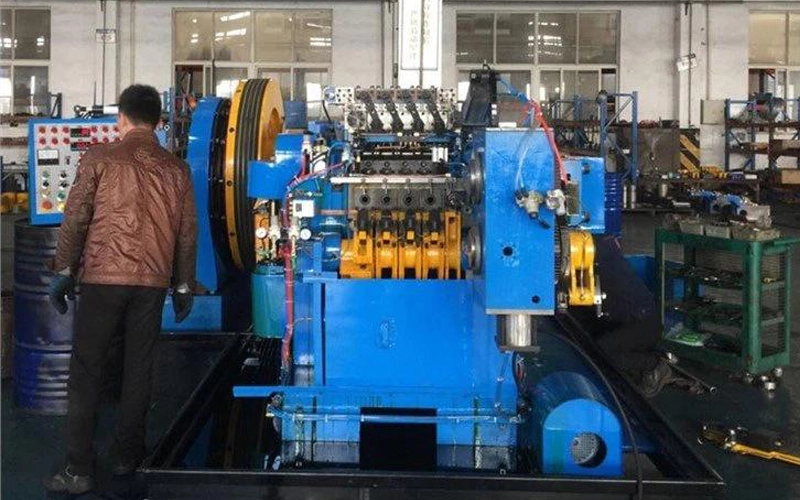

Advanced Technology: Our state-of-the-art machinery ensures precision and efficiency in every project.

Expert Team: With years of experience, our engineers deliver innovative solutions for complex requirements.

Customization: We offer tailored designs to meet your specific applications and industry standards.

Quality Assurance: Strict quality control processes guarantee flawless results every time.

Global Reach: We serve clients worldwide, delivering reliable and cost-effective solutions.

Cold forging is a transformative manufacturing process that combines strength, precision, and efficiency. Whether you’re in automotive, aerospace, or electronics, this method can elevate your production capabilities. At Shengtuo Machine, we’re committed to delivering top-notch cold forging solutions that drive your business forward.

Thread Cold Rolling Machine

ST-4R-50 High-Speed Thread Rolling Machine ST-8R-83(120) High-Speed Thread Rolling Machine ST-6R-80 High-Speed Thread Rolling Machine ST-4A-50 High-Speed Thread Rolling Machine ST-4A-25 High-Speed Thread Rolling Machine ST-10N-150 High-Speed Thread Rolling Machine ST-30N High-Speed Thread Rolling Machine ST-60N(M16-150) High-Speed Thread Rolling Machine ST-60N(M16-200) High-Speed Thread Rolling Machine ST-12N-150 High-Speed Thread Rolling Machine ST-3A-25 High-Speed Thread Rolling Machine ST-3 High-Speed Thread Rolling Machine ST-80N High-Speed Thread Rolling Machine ST-90S High-Speed Thread Rolling Machine ST-100-M40 High-Speed Thread Rolling Machine ST-70N End Milling Machine

Thread Cold Rolling Machine

ST-4R-50 High-Speed Thread Rolling Machine ST-8R-83(120) High-Speed Thread Rolling Machine ST-6R-80 High-Speed Thread Rolling Machine ST-4A-50 High-Speed Thread Rolling Machine ST-4A-25 High-Speed Thread Rolling Machine ST-10N-150 High-Speed Thread Rolling Machine ST-30N High-Speed Thread Rolling Machine ST-60N(M16-150) High-Speed Thread Rolling Machine ST-60N(M16-200) High-Speed Thread Rolling Machine ST-12N-150 High-Speed Thread Rolling Machine ST-3A-25 High-Speed Thread Rolling Machine ST-3 High-Speed Thread Rolling Machine ST-80N High-Speed Thread Rolling Machine ST-90S High-Speed Thread Rolling Machine ST-100-M40 High-Speed Thread Rolling Machine ST-70N End Milling Machine English

English 中文

中文