-

Products

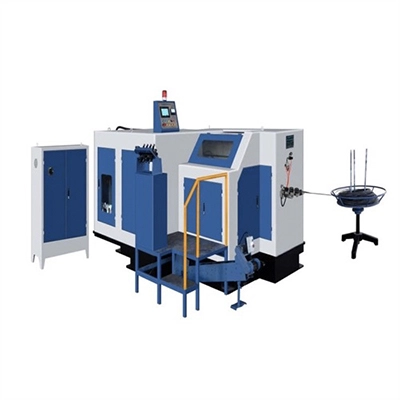

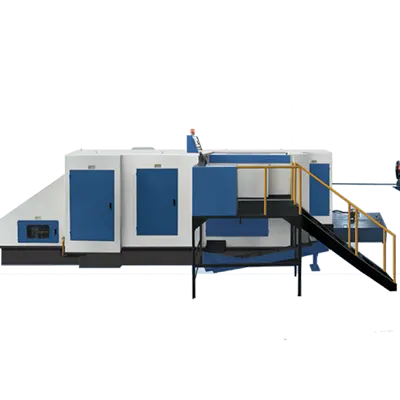

Thread Cold Rolling Machine

ST-4R-50 High-Speed Thread Rolling Machine ST-8R-83(120) High-Speed Thread Rolling Machine ST-6R-80 High-Speed Thread Rolling Machine ST-4A-50 High-Speed Thread Rolling Machine ST-4A-25 High-Speed Thread Rolling Machine ST-10N-150 High-Speed Thread Rolling Machine ST-30N High-Speed Thread Rolling Machine ST-60N(M16-150) High-Speed Thread Rolling Machine ST-60N(M16-200) High-Speed Thread Rolling Machine ST-12N-150 High-Speed Thread Rolling Machine ST-3A-25 High-Speed Thread Rolling Machine ST-3 High-Speed Thread Rolling Machine ST-80N High-Speed Thread Rolling Machine ST-90S High-Speed Thread Rolling Machine ST-100-M40 High-Speed Thread Rolling Machine ST-70N End Milling Machine

Thread Cold Rolling Machine

ST-4R-50 High-Speed Thread Rolling Machine ST-8R-83(120) High-Speed Thread Rolling Machine ST-6R-80 High-Speed Thread Rolling Machine ST-4A-50 High-Speed Thread Rolling Machine ST-4A-25 High-Speed Thread Rolling Machine ST-10N-150 High-Speed Thread Rolling Machine ST-30N High-Speed Thread Rolling Machine ST-60N(M16-150) High-Speed Thread Rolling Machine ST-60N(M16-200) High-Speed Thread Rolling Machine ST-12N-150 High-Speed Thread Rolling Machine ST-3A-25 High-Speed Thread Rolling Machine ST-3 High-Speed Thread Rolling Machine ST-80N High-Speed Thread Rolling Machine ST-90S High-Speed Thread Rolling Machine ST-100-M40 High-Speed Thread Rolling Machine ST-70N End Milling Machine - Company

- Technology

- Manufacturing

- Resources

- News

- Contact Us

English

English 中文

中文