The stabbing mechanism of the cold heading machine adopts a computer-designed and processed cam to achieve the purpose of stabilizing and rapid stabbing. The roller shaft of the cutting part adopts bidirectional support to ensure that the scissors rod has sufficient rigidity. Each clamp of the clamp transmission system has a pair of planetary gears, which can control the flip and translation of the clamp to achieve accurate and stable feeding.

Precautions when using cold heading machine

1. Before mechanical operation, fill in lubricating oil or press-made oil first, please refer to the explanation of lubricating system for the oil capacity and viscosity index.

2. The cold heading machine is equipped with an air pressure clutch brake. An air pressure storage container should be equipped in front of the mechanical air pressure three-point combination. It can be used by two units in one container or used alone. For the standard of use, please refer to the SR clutch size. Air meter for driving school bus.

3. It is necessary to pay attention to the level of the machine in the front and back, left and right directions when installing to ensure the stability of mechanical operation.

4. The diameter of the power distribution device cable of the machinery should not be smaller than the main switch cable on the mechanical control box. It is necessary to connect the motor and electrical control box with different grounding to avoid damage to the machine and personnel when leakage occurs.

5. When the machine is hoisted, two steel cables with a diameter of Φ25 or more must be used for hoisting. First, open the operating door cover of the machine and the rear upper cover of the main sliding table, and hang the steel cables to the four-corner booms on the main table of the machine. The angle of the sling should not exceed 60°. It is necessary to pay attention to the sling not to collide with the mechanical parts and the shell when lifting.

6. Before starting the machine, check whether the wire connectors are loose and whether the machine screws are loose. After the machine has been working for a period of time, it is necessary to check whether the screws of various parts are loose and whether the oil circuit is normal.

7. Start the cold heading machine, first start the smooth pump, it is necessary for the smooth indicator blue light to turn on, indicating that the smooth pump is operating normally, and then start the main motor. At this time, the air pressure needs to reach 5.5~6.0 kg/c㎡. Inching operation, perform various stages of movement to check whether the machine is working smoothly. After everything is normal, press the single stroke to check whether it is normal. When parking for single stroke and general operations, it is necessary that the main slide of the machine can be parked behind. In order to facilitate the adjustment operation, otherwise it is necessary to adjust the cam viewpoint position of the electric appliance controlled by the parking space. This will be adjusted due to the different speed. When performing inching operation, the interval between each inching operation should be more than 2 seconds. This pair of clutches will not have abnormal wear. When the machine is equipped with a variable speed device, the machine should try to perform the operation of the inching school bus at a slow speed. In order to reduce the slip and wear caused by the clutch during high-speed operation and transmission.

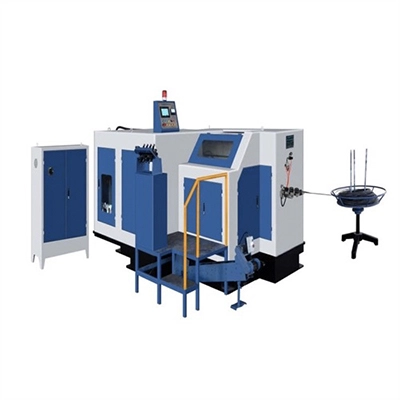

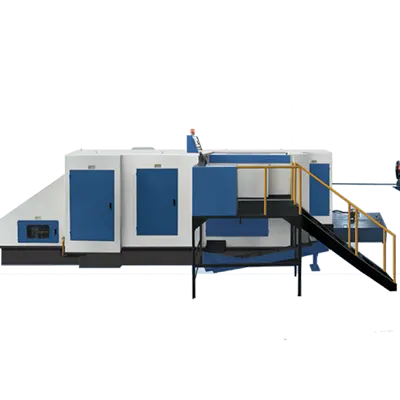

Thread Cold Rolling Machine

ST-4R-50 High-Speed Thread Rolling Machine ST-8R-83(120) High-Speed Thread Rolling Machine ST-6R-80 High-Speed Thread Rolling Machine ST-4A-50 High-Speed Thread Rolling Machine ST-4A-25 High-Speed Thread Rolling Machine ST-10N-150 High-Speed Thread Rolling Machine ST-30N High-Speed Thread Rolling Machine ST-60N(M16-150) High-Speed Thread Rolling Machine ST-60N(M16-200) High-Speed Thread Rolling Machine ST-12N-150 High-Speed Thread Rolling Machine ST-3A-25 High-Speed Thread Rolling Machine ST-3 High-Speed Thread Rolling Machine ST-80N High-Speed Thread Rolling Machine ST-90S High-Speed Thread Rolling Machine ST-100-M40 High-Speed Thread Rolling Machine ST-70N End Milling Machine

Thread Cold Rolling Machine

ST-4R-50 High-Speed Thread Rolling Machine ST-8R-83(120) High-Speed Thread Rolling Machine ST-6R-80 High-Speed Thread Rolling Machine ST-4A-50 High-Speed Thread Rolling Machine ST-4A-25 High-Speed Thread Rolling Machine ST-10N-150 High-Speed Thread Rolling Machine ST-30N High-Speed Thread Rolling Machine ST-60N(M16-150) High-Speed Thread Rolling Machine ST-60N(M16-200) High-Speed Thread Rolling Machine ST-12N-150 High-Speed Thread Rolling Machine ST-3A-25 High-Speed Thread Rolling Machine ST-3 High-Speed Thread Rolling Machine ST-80N High-Speed Thread Rolling Machine ST-90S High-Speed Thread Rolling Machine ST-100-M40 High-Speed Thread Rolling Machine ST-70N End Milling Machine English

English 中文

中文