1. Handheld automatic lock screw machine

Compared with the locking screw action of holding the screw in one hand, holding the electric screwdriver or air screw in the other hand, the automatic lock screw machine can free one hand out, and only need a hand-held screwdriver to align the screw hole to lock the screw. After locking a screw, you only need to lift the screwdriver to align with the next screw hole to lock the screw. The machine will automatically transport a screw to the screwdriver at the moment of lifting the screwdriver, wait for the next screw to be locked, and repeat.

1. Hand-held automatic screw-locking machine, screw conveying and locking can be done in one go, no longer taking screws by hand. The screwing speed is 40-60PCS/MIN, which greatly improves production efficiency and saves labor. You can drive as fast as you can!

2. Each time a screw is finished, the feeding mechanism will automatically send the screw to the batching nozzle, eliminating the need to grab the screw by hand, move and align it.

3. As long as you directly align the screw holes and press the screw lightly, it will be locked. There is no repeated feeding phenomenon. It is convenient and quick to lock one pellet to one pellet.

4. It can be equipped with your company's original electric batch and wind batch, no need to purchase new electric batch and wind batch, the torque adjustment is the same as your original adjustment method, saving the purchase cost!

5. The electric batch cover is quite light, so there is no need to worry about increasing the fatigue of workers due to the heavy head!

6. It can be operated as a stand-alone machine or can be configured as an assembly line. Loading and unloading forms. Quickly improve the quality of screw locking and greatly improve production efficiency.

7. Hand-held lock screw machines are used in automatic assembly lines in the electronics industry, such as mobile phones, hard drives, keyboards, computers, DVD appliances, fans, electronics, plastics, toys, electrical appliances, communication equipment, electrical appliances, toys, and electronics processing plants.

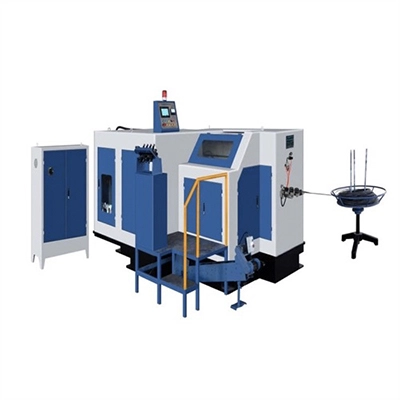

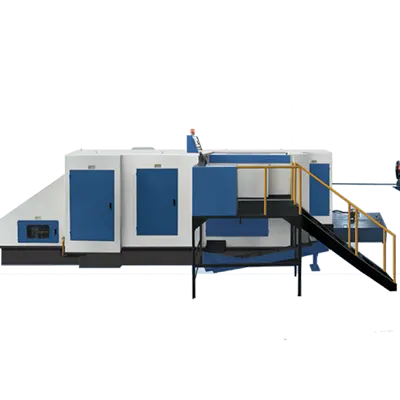

2. Automatic lock screw machine

On the basis of the automatic feeding of the hand-held automatic lock screw machine, it has added functions such as a robot arm or assembly line, workbench, automatic control positioning, etc., which is the TOP product of the lock screw machine. Unmanned monitoring can be implemented according to customer site requirements, which not only saves labor costs but also improves production and assembly efficiency.

It can be designed as a horizontal, oblique and multi-directional simultaneous locking mechanism to meet a variety of production needs.

Intelligent-continuous feeding, constant torque, optional counting function, anti-leakage function. Screw sliding teeth and floating lock detection.

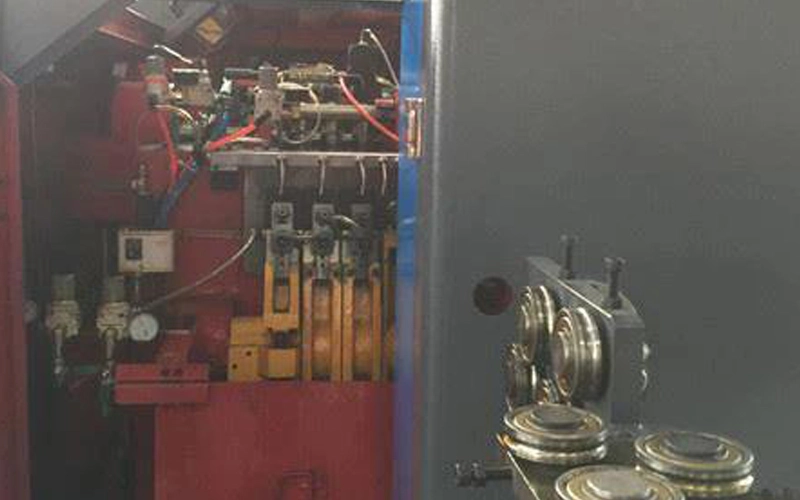

Thread Cold Rolling Machine

ST-4R-50 High-Speed Thread Rolling Machine ST-8R-83(120) High-Speed Thread Rolling Machine ST-6R-80 High-Speed Thread Rolling Machine ST-4A-50 High-Speed Thread Rolling Machine ST-4A-25 High-Speed Thread Rolling Machine ST-10N-150 High-Speed Thread Rolling Machine ST-30N High-Speed Thread Rolling Machine ST-60N(M16-150) High-Speed Thread Rolling Machine ST-60N(M16-200) High-Speed Thread Rolling Machine ST-12N-150 High-Speed Thread Rolling Machine ST-3A-25 High-Speed Thread Rolling Machine ST-3 High-Speed Thread Rolling Machine ST-80N High-Speed Thread Rolling Machine ST-90S High-Speed Thread Rolling Machine ST-100-M40 High-Speed Thread Rolling Machine ST-70N End Milling Machine

Thread Cold Rolling Machine

ST-4R-50 High-Speed Thread Rolling Machine ST-8R-83(120) High-Speed Thread Rolling Machine ST-6R-80 High-Speed Thread Rolling Machine ST-4A-50 High-Speed Thread Rolling Machine ST-4A-25 High-Speed Thread Rolling Machine ST-10N-150 High-Speed Thread Rolling Machine ST-30N High-Speed Thread Rolling Machine ST-60N(M16-150) High-Speed Thread Rolling Machine ST-60N(M16-200) High-Speed Thread Rolling Machine ST-12N-150 High-Speed Thread Rolling Machine ST-3A-25 High-Speed Thread Rolling Machine ST-3 High-Speed Thread Rolling Machine ST-80N High-Speed Thread Rolling Machine ST-90S High-Speed Thread Rolling Machine ST-100-M40 High-Speed Thread Rolling Machine ST-70N End Milling Machine English

English 中文

中文